B Corp or EcoVadis, what’s the best choice for your company?

B Corp or EcoVadis, what’s the best choice for your company?

“Sustainability in manufacturing is more than compliance, it’s a strategic journey of innovation, resilience, and measurable impact.”

Sustainability in manufacturing has evolved from a compliance checkbox to a strategic imperative, which drives innovation, resilience, and competitive advantage. The sector faces escalating environmental pressures alongside social and regulatory demands. Manufacturing companies must prepare for a comprehensive transformation. Understanding the nuanced ESG trends within manufacturing—and responding effectively—is essential for companies aiming to lead in this changing landscape.

Trend #1: Tackling the carbon footprint beyond the factory gate

Manufacturing is traditionally resource and energy intensive, contributing significantly to global greenhouse gas (GHG) emissions.

Did you know?

- Scope 3 emissions on average are 26 times higher than a manufacturer’s direct (Scope 1 and 2) emissions, originating primarily from upstream suppliers and raw material extraction (1)

- Energy consumption in manufacturing constitutes nearly 25% (in 2022) of global industrial CO₂ emissions (2)

The growing scrutiny on indirect emissions reflects a shift in responsibility. Regulators, investors, and customers demand transparency – not just on owned operations but across supply chains. Manufacturing companies must decarbonise upstream activities, but what does this involve?

- Collaborating closely with suppliers on emissions data reporting

- Consider co-financing such as mutual investments and co-development initiatives

- Developing supplier engagement programmes that incentivise emission reductions

- Using digital carbon accounting tools for robust transparency and traceability

Companies investing in mature Scope 3 measurement capabilities often unlock strategic value: they can mitigate risks and enhance supply chain resilience (3).

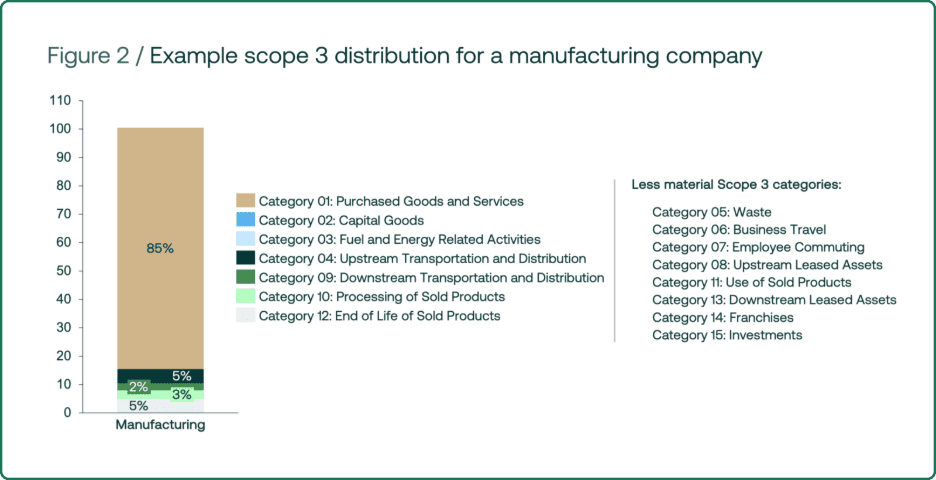

Distribution of emissions in the manufacturing sector

In manufacturing, the majority of Scope 3 emissions—typically 70–90% in our anonymised case, come from Category 1: Purchased Goods and Services. This reflects the resource-intensive nature of the sector, where extracting, processing, and transporting raw materials and components drives most upstream emissions.

Smaller but notable contributions come from Category 12: End-of-Life Treatment of Sold Products, while Category 4: Upstream Transportation and Distribution usually represents 1–10%, and Category 9: Downstream Transportation and Distribution about 1–5% of total Scope 3 emissions.

While this breakdown is common across the industry, it may vary for manufacturers with distinct supply chains or business models.

Source: Anonymised emissions data of Nexio Projects client

Trend #2: Redefining resources and waste through circular economy

Circularity has emerged as a critical strategy for sustainable manufacturing, focusing on extending product lifecycles and reducing waste. Key trends include:

- Adoption of resource-efficient manufacturing processes incorporating renewable, recycled and responsibly sourced materials

- Implementation of design for durability, reusability, disassembly, repairability (e.g. modular), and recyclability to reduce product obsolescence

- Initiatives on refurbish, reuse, repair, recycle and waste minimisation, such as zero-waste certification programmes

- Evaluation of supply chain risks to help build more resilient supplier networks

- Innovate new product-service systems such as product-as-a-service models or shared platforms

- Repurpose or recover products, materials, or components for different uses when original use is obsolete

- Eliminate unnecessary materials from product life-cycle (e.g. packaging size)

Nexio Projects helps organisations in manufacturing and other sectors engage their supply chain. See our supplier engagement solution and activate your value chain for a more circular future.

According to a 2024 survey (4), companies embedding circular practices reported:

- Average reductions of 20% in raw material costs

- An 18% increase in customer loyalty tied to sustainable product attributes

Regulatory drivers for circularity

European initiatives, such as the Circular Economy Action Plan, the overarching Eco‑design for Sustainable Products Regulation (ESPR) and extended producer responsibility (EPR) schemes, require manufacturers to innovate product design and waste management, thereby impacting competitiveness and compliance (5).

The ESPR specifically aims to improve product circularity, energy performance, durability, recyclability and reparability across nearly all physical product categories, setting harmonised EU-wide sustainability standards. This makes it an essential framework for manufacturers seeking to future-proof their products and meet tightening regulatory demands.

Trend #3: Navigating an evolving regulatory frameworks

Manufacturers face an increasingly stringent regulatory environment designed to accelerate sustainable industrial practices globally. Recent developments include:

- The EU’s Corporate Sustainability Reporting Directive (CSRD) mandates in-depth ESG disclosures, with detailed standards for environmental impact, social responsibility, and governance structures

- The full Carbon Border Adjustment Mechanism (CBAM) operational system starting in 2026 imposes carbon tariffs on imports (cement, iron and steel, aluminium, fertilisers, electricity and hydrogen), compelling manufacturers to reduce embedded emissions or face economic penalties

- Expanding adoption of sustainability disclosure standards such as IFRS S2 and frameworks like TCFD aligns financial and climate-risk reporting

- For CSDDD, companies must identify, prevent, mitigate and account for adverse human-rights and environmental impacts in their own operations, subsidiaries, and value chains (including suppliers & business partners

- EUD prohibits placing on EU market certain commodities and derived products that have been produced on deforested or degraded land

For instance, companies compliant with CSRD are anticipated to benefit from improved investor confidence and reduced regulatory costs, while non-compliance risks include market exclusion and reputational damage (6).

Our reporting guide tackles different reporting frameworks and explores topics such as interoperability. Download here!

Trend #4: Amplifying ethical and labour standards

ESG in manufacturing cannot solely focus on environmental challenges. The sector must also reinforce:

- Employee safety and wellbeing, prioritising rigorous health and safety protocols

- Respect for human rights across the entire value chain, including the supply chain, with fair labour practices and conflict-free sourcing

- Diversity, equity, and inclusion (DEI), enhancing workforce innovation and stakeholder trust

Download our DEI guide to act in social responsibility for your organisation.

Recent data highlights that manufacturers with robust social governance report 23% higher employee retention and significantly fewer labour disputes (7).

Trend #5: Innovation and digitalisation as enablers of sustainable manufacturing

Digital technologies serve as critical enablers in ESG performance enhancement:

- IoT sensors and AI-driven analytics improve energy efficiency and predictive maintenance, reducing downtime and emissions

- Blockchain and digital traceability platforms increase supply chain transparency and ethical sourcing verification

- Advanced simulation tools facilitate lifecycle assessments and material substitution decisions, accelerating decarbonisation initiatives

Moreover, 65% of manufacturers investing in digital sustainability solutions report enhanced ESG reporting accuracy and accelerated goal achievement (P8).

Read our AI prompting guide series to unlock digitalisation opportunities for your sector.

Testimonials: Our expertise in the manufacturing sector

ESG challenges in manufacturing are complex and require trusted partnerships grounded in expertise and collaboration. Years of working closely with a diverse range of manufacturing clients have allowed us to develop deep insights and proven approaches to advancing sustainability performance. The three cases below highlight some of the success stories from this extensive experience, illustrating how collaborative engagement and tailored strategies have delivered real value across different contexts and scales.

Nexio Projects partnered with i-team Global to develop a thorough greenhouse gas inventory focusing on Scopes 1 and 2. This initiative laid the groundwork for expansive supply chain emissions management, while our collaborative approach advanced their EcoVadis rating and systematically embedded sustainability leadership into all departments.

“The highlight of working with Nexio Projects has been the feeling that we are in control and actually creating the impact we set out to achieve.”

– Ron van der Ven, Global ESG Ambassador at i-team Global

Nexio Projects collaborated with Rose Acre Farms, a supplier for Unilever, to develop a comprehensive Product Carbon Footprint (PCF) framework for a liquid egg product. This project mapped emissions across the entire supply chain, including feed, energy, and hen productivity, enabling accurate attribution of emissions throughout production stages. Our partnership equipped Rose Acre Farms with advanced modelling tools and streamlined methodologies, enhancing transparency and stakeholder engagement, especially with Unilever, while building a scalable approach for ongoing and future carbon assessments.

“Nexio Projects enabled us to successfully perform a complex PCF calculation, giving us the confidence to report on and accelerate our sustainability progress.”

– Doster Harper, Director of Sustainability at Rose Acre Farms

These examples underscore our commitment to adapting sustainability solutions fit for the scale and complexity of modern manufacturing, driving measurable impact that aligns with regulatory and market demands. See more case studies here.

Nexio Projects’ added value

Working with Nexio Projects means gaining a partner invested in your sustainability journey. As a top ten boutique ESG and sustainability consultancy (Verdantix 2024), Nexio Projects helps organisations break down complex challenges and target ambitious climate action. Our expertise spans strategic reporting, implementation and ESG framework integration, supported by an in-house team of certified B Leaders and strategic EcoVadis partner status since 2018.

Nexio Projects boasts extensive experience across more than 25 sectors, with a strong focus on the manufacturing industry where we support over 55 clients through numerous successful projects. Our team of award-winning consultants combines deep industry knowledge with practical sustainability expertise to deliver tailored solutions that drive measurable impact. Since achieving B Corp certification in 2019, we have partnered with organisations worldwide, transforming manufacturing operations alongside experts in shipping, logistics, chemicals, and consumer goods.

Ready to advance your ESG journey?

Speak to one of our experts to learn how Nexio Projects can guide your ESG transformation and help you reach sustainability leadership.

Subscribe to our newsletter to get the latest ESG updates and best practices delivered directly to your inbox.

References

- CDP (2024) Corporates’ supply chain scope3 emissions are26 times higher than their operational emissions. Available at: https://www.cdp.net/en/press-releases/corporates-supply-chain-scope-3-emissions-are-26-times-higher-than-their-operational-emissions (Accessed:19 November2025).

- IEA (2025) Industry. Available at: https://www.iea.org/energy-system/industry (Accessed:19 November2025).

- McKinsey & Company (2024). Carbon Transparency and Supply Chain Resilience Report. Available at: https://www.mckinsey.com/capabilities/sustainability/our-insights (Accessed: 19 November 2025).

- Boston Consulting Group (2024). Circular Economy in Manufacturing Survey. Available at: https://www.bcg.com/publications/collections/circular-economy (Accessed: 19 November 2025).

- European Commission (2023). Circular Economy Action Plan and CBAM Regulations. Available at: https://environment.ec.europa.eu/strategy/circular-economy_en (Accessed: 19 November 2025).

- Deloitte (2025). CSRD and ESG Compliance in Manufacturing. Available at: https://www2.deloitte.com/global/en/pages/about-deloitte/articles/csrd-esg-compliance.html (Accessed: 19 November 2025).

- Responsible Business Alliance (RBA) (2024). Social Governance and Labour Standards Report. Available at: https://www.responsiblebusiness.org/media/docs (Accessed: 19 November 2025).

- PwC (2024). Digital Transformation in Manufacturing and ESG Performance. Available at: https://www.pwc.com/gx/en/industries/industrial-manufacturing.html (Accessed: 19 November 2025).