Why should you develop an SBTi-validated emissions reduction target?

Why should you develop an SBTi-validated emissions reduction target?

“Meaningful engagement with suppliers multiplies impact across the system. Clear expectations, shared roadmaps amplify results.”

Decarbonisation stands as a critical imperative for businesses aiming towards achieving Net Zero, requiring scrutiny across Scopes 1, 2, and 3 to address the full spectrum of emissions. Building on Part 1 which covered understanding GHG emissions and carbon accounting, and Part 2, which detailed turning carbon data into Science Based Target Initiative-aligned goals, this instalment dives into actionable carbon emissions reduction strategies. Through value chain engagement, companies can unlock systemic change, turning complex supply chains into engines of decarbonisation.

Introduction to sustainable supply chains

Climate change drives long-term shifts such as rising temperatures, extreme weather, sea-level rise, and ecosystem disruption, demanding urgent business action through operations and supply chains. Businesses contribute heavily to emissions but also hold power for innovation and positive impact via sustainable practices.

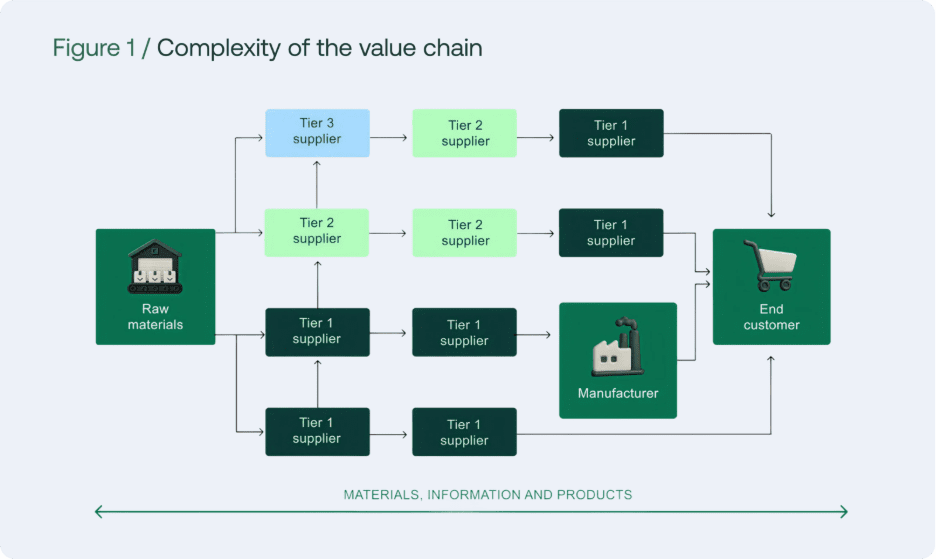

Collaborative efforts across the value chain prove essential, as individual actions fall short against global impacts. Current challenges include supply chain complexity, maturity variability, data capture difficulties from estimates versus activity data, regulatory time constraints, knowledge gaps, greenwashing risks, and unintended consequences like material price spikes or excessive requests.

Drivers persist from investor and regulatory demands, market risks from weather and geopolitics, reputational and operational risks, plus competitive advantages. Supply chain transparency emerges as key to responsible supply chain management.

Identifying carbon hotspots

Many overlook supply chain emissions despite their visibility, often aggregating them broadly into generic categories. Hotspots typically dominate in purchased goods and services, use of sold products, upstream transportation, downstream transport, and other areas.

Complex supply chains, from raw materials through multi-tier processing to end customers, hinder accurate data flow, amplifying Scope 3 challenges. Materiality assessments pinpoint these hotspots by emissions volume, risk levels, maturity gaps, or strategic importance to enable focused supplier engagement.

Practical strategies to stay on top

- Materiality assessment: Identify emissions hotspots and prioritise based on risk, maturity levels, and strategic importance to focus efforts effectively.

- Identify benefits and barriers: Evaluate resources required, integration challenges, innovation opportunities, and necessary investments to understand feasibility.

- Data management: Implement continuous improvements, transitioning from estimates to reliable activity data for accurate carbon accounting.

- Design collaborative engagement programmes: Develop training, upskilling initiatives, and material resources to foster capacity building across the supply chain.

- Implementation planning: Establish strong governance, realistic timelines, capacity building measures, KPIs, and targets to drive sustainable procurement progress.

Sector-specific strategies

Logistics

Logistics often involve specialised, time-critical transport, driving Scope 1 vehicle emissions and high Scope 3 impacts.

- Air-to-sea/rail mode shift: Non-urgent long-haul shipments reduce emissions through planning and freight alignment, requiring moderate effort via pilots then rollout. Key stakeholders include supply chain planning, procurement, and regional logistics teams.

- Route optimisation/load factors: Digital tools cut empty miles and boost utilisation with low-to-medium effort through system updates. This involves logistics operations, transport planning, IT, and 3PL partners.

- EVs/alternative fuels: Urban EVs combined with HVO100 biofuels decarbonise last-mile diesel routes, featuring low operational effort and moderate procurement needs. Engage sustainability, fleet management, OEMs, and 3PLs.

Manufacturing

Energy-intensive sites fuel Scope 1 and 2 emissions, while renewables procurement cuts Scope 3 from purchased goods.

- Energy efficiency: Upgrade compressed air systems, motors, and HVAC while retiring from old equipment, demanding medium-to-high effort with audits and investments. Regional leads, finance, and operations teams drive this.

- Electrification: Target high-emission heat and processes for fossil fuel replacement, with medium-to-high capital expenditure prioritised by intensity. The same stakeholders lead.

- Renewable electricity: Implement PPAs, RECs, on-site solar, or green tariffs across sites with low-to-medium effort. Sustainability/ESG, operations, and procurement teams take the lead.

Materials and packaging

A significant source of Scope 3 emissions exists across multiple categories. Optimising these areas can greatly reduce emissions from production, transportation, and product disposal.

- Recycled/bio-based feedstocks: Phase out virgin materials through low-to-medium effort swaps or minor upgrades. Procurement, sustainability, and R&D teams collaborate.

- High-impact materials: Apply renewables to irreplaceable glass, plastics, or aluminium with medium effort linked to manufacturing energy. Operations prioritise energy-intensive items.

- Lightweight redesign: Reduce weight for dual material and transport savings, requiring medium-to-high effort with compliant testing. Involves procurement, R&D, and sustainability teams.

Supplier engagement for greater impact

Target top suppliers responsible for 80% of emissions to maximise efficiency, integrating sustainability into core processes, measuring concrete actions, and redesigning systemically. Avoid common pitfalls like scattered priorities, weak business cases, reporting-only focus, one-size-fits-all approaches, and poor follow-through.

- Awareness/capacity building: Set harmonised expectations with simple training targeted at high-impact regions, highlighting energy savings and competitiveness benefits.

- Tools for decarbonisation roadmap: Use scorecards blending climate performance with quality and cost metrics, maturity models, questionnaires, PCF and renewables training, plus site roadmaps for projects.

- Incentives: Offer preferential contracts, climate awards, co-investments, and long-term pilots to shift from compliance to active collaboration.

Next steps

Identify material, manufacturing, and logistics hotspots to drive meaningful impact, prioritising efficiency measures and renewable solutions that often reduce costs. Deep, genuine collaboration with suppliers can further accelerate progress through shared roadmaps and greater supply chain transparency.

Embrace a multi-year journey with these essentials: leadership sponsorship and governance structures, resource allocation for quick wins plus long-term capabilities, and full business integration for transformation and growth.

How Nexio Projects supports supply chain decarbonisation

Nexio Projects delivers tailored supplier engagement programmes, supporting organisations from strategic gap analysis to outsourced sustainability management. As an international sustainability consultancy, we help companies move from compliance to purpose, translating sustainability ambitions into concrete actions that strengthen ESG performance across the value chain.

Through structured ESG assessments, regulatory gap analyses, and bespoke due diligence frameworks, clients gain clarity on supplier segmentation and risk prioritisation in line with their specific industry context. Our experts guide carbon footprinting, Science Based Target initiative validation, and capacity building through customised training programmes and multilingual workshops aimed at improving supplier capability and compliance.

By leveraging digital platforms and co-created engagement strategies, Nexio Projects fosters collaboration between buyers and suppliers worldwide, enhancing transparency, enabling continuous performance improvement, and driving shared responsibility for sustainable procurement. Ultimately, these tailored programmes empower organisations to advance carbon emissions reduction strategies, embed responsible sourcing practices, and accelerate progress towards net-zero value chains.

Ready to act on your decarbonisation journey? Contact us and our experts will support your organistion.

If you are interested in monthly ESG news, regulatory updates and best practices, sign up to our newsletter and receive them in your inbox.